How Bamboo Flooring is Manufactured

Explore the intricate process of transforming bamboo into durable and beautiful flooring materials. Learn about the harvesting, treatment, and manufacturing techniques involved in creating various types of bamboo flooring. Gain insights into quality control measures, adhesive options, and finishing processes that contribute to the production of high-quality bamboo flooring

Bamboo Flooring Manufacturing Process

Bamboo floors are like snowflakes—no two are alike! Okay, not completely, but there are a number of different kinds of bamboo that are all manufactured in huge array of ways to achieve the color, texture, and durability people look for. To understand a little bit more about which bamboo flooring might be right for you, here is information on how bamboo flooring is made.

- Step 1: Harvesting the Bamboo

- Step 2: Pest & Decay Prevention

- Step 3: Carbonization

- Step 4: Moisture Balancing

- Step 5: Strip Milling & Prep

- Step 6: Finish Process

- Step 7: Quality Control and Packaging

How is strand woven bamboo flooring manufactured?

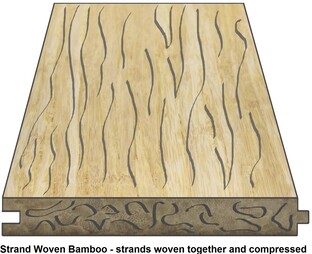

The strongest and most durable type of bamboo flooring is strand woven bamboo flooring. It is made by separating the fibers bamboo and then compressing them in the following process to make a stylish and tough flooring.

- The bamboo is harvested by cutting the stalks. If you didn’t already know, bamboo doesn’t have to be chopped down like trees, so the bottom of the stalk remains to grow more bamboo.

- After being harvest, the stalks are cut into strips and then shredded down to their fibers. Different from the fibers of trees, these bamboo fibers are pliable and can be woven together. They’re cool like that because bamboo is a grass.

- Fibers maybe be left as a natural color, or they can be heated or boiled to turn a darker brown color. They can also be stained.

- The fibers are then combined with resin and compressed with extreme heat and pressure. This forms a solid block of strand woven bamboo material.

- This solid material is cut into planks during the machining process. These extremely hard planks can then be coated or veneered along with having protective layers added to the surface to increase the floor’s durability.

- A tongue and groove surface or other fastening system are machined into the planks before finishing and packaging them for shipping and sale.

- Voila! Once finished, strand woven bamboo flooring is the hardest wood flooring in the market.

How is Traditional Bamboo Floor (horizontal and vertical) manufactured?

Unlike strand woven bamboo floors, traditional bamboo flooring is made with intact sections of the bamboo stalk. The plank may or may not show some of the original bamboo structure and the grain of the bamboo. Some do and some don’t, so it just depends on the style that’s being manufactured. Like strand woven floors, it can come in a number of fancy and fun colors or textures, and is still engineered to be very strong flooring for a number of applications.

- Again, bamboo is harvested by the bamboo lumberjacks who cut the stalks while leaving the root system intact to continue growing more bamboo.

- Bamboo is put through a machine that cuts the stalks to the appropriate size and splits the shafts accordingly. The material must be crosscut to identical lengths along with removing the inside of the knots that divide the sections (known as knuckles). An outer skin is peeled off as well.

- To clean the bamboo and prevent it from breaking down, the material is boiled. This removes dirt, debris, and sugars made by the plant while it grows. It must be air dried and put through a kiln to reach the desired dryness (somewhere between 8 and 14 percent moisture), a process which usually takes about 5 days.

- The bamboo can also be steamed or heated for a longer period to create a carbonization effect. Due to the high heat, the bamboo turns a deeper brown as the sugars in the bamboo are caramelized. Mmm, it’s like the difference between regular sugar and brown sugar, right?

-

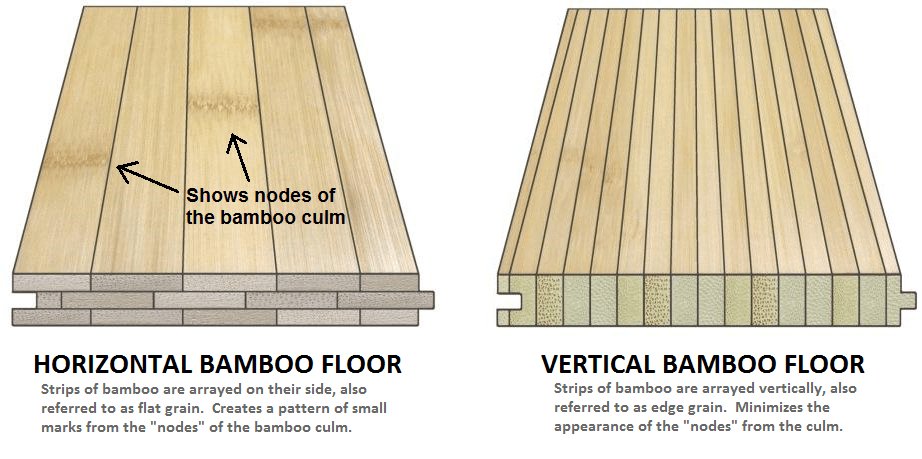

Strips are either turned on end to create a “vertical” grain, or laid flat to create a “horizontal” grain, which are arrayed carefully and then laminated together. Horizontal planks may show the ‘node’ of the bamboo plant while vertical pieces show such a small strip that the lines and knuckles are not distinguishable.

![horizontal vertical bamboo floor]()

- The bamboo planks are finished as needed with sanding to provide a smooth surface for the floor.

- After final sanding and finishing, planks are inspected, packaged, and readied for sale or shipping.

Bamboo Flooring Colorization Process

Carbonization of bamboo floors is performed by heating the bamboo under controlled circumstances. The darker color is a result of the sugars in the bamboo caramelizing due to the high heat. The longer the bamboo is allowed to stay at a high temperature, the darker the color of the planks will be. The end result will still be a very durable floor, but carbonization does weaken the fibers somewhat, making the flooring slightly softer. The strength of the flooring will be reduced between 10 and 30 percent.

Alternatively, bamboo flooring can be bleached with lightening agents that remove color, or it can be painted or stained to reach a darker color or any one of many shades. Luster can also be added to have a muted or gloss finish, with many options of variance in between.

Bamboo Floor Finishes

Awesome technological advances have led to pretty fancy finishes when it comes to bamboo flooring. Unlike the old-school polyurethane options—or lack of options—there are now several materials and processes used that add to the benefits of prefinished floors.

- Water-based materials have been created for many industries that are now also available for bamboo flooring. These are better for the environment and add to the sustainable benefits of bamboo.

- Acrylic urethane offers added durability and bonds to the planks for a strong finish with a nice look.

- UV-curing is a process used to cure the finish to the wood. By using UV rays, the manufacturing is greener and healthier for production employees because there’s less off-gassing.

- Aluminum oxide: this is a layer added during production that greatly increases the strength of the finish by including a coating of fine metal chips under the finish.

- Some floors now boast UV protection as well, keeping floors from fading and wearing due to the sun.

- Other materials may be added in finishing to increase the bamboo flooring’s scratch resistance and ability to resist water.

Prefinished vs. Unfinished

When buying bamboo and hardwood flooring, you have the option to get it prefinished or unfinished. When unfinished, finish is added after installation. Some people mistakenly believe that it’s better to buy the flooring unfinished and have this step completed after the flooring is installed. In reality, there are many benefits to prefinished flooring.

- Easy Installation - Installing prefinished flooring is much easier than installing a floor that has yet to be finished. With most methods for installing a finished floor, the room can go back to normal almost immediately. There’s no need to wait to bring in furniture or begin walking through the room. This is not true for unfinished floors that are finished on-site.

- Fast, No Mess - The finishing process is smelly, with odors lasting even after the finish dries. Plus, it may take several hours to even days between coats on the finish, so it is a much longer process.

- Added Durability - Companies can use much more durable finish during the manufacturing process. On-site finishers are not able to get the same strength finish for layering onto the flooring once it is installed, to pre-finished flooring tends to hold up better than unfinished.

The only real drawbacks to prefinished floors are that they can be harder to repair or refinish. Because the finish is so strong, it’s more difficult to scratch it, but once scratched, it’s not as easy to sand a spot down and fix the finish. The same goes for refinishing. If you wanted to refinish your floors in the future, it’s more difficult and takes more work to remove the factory finish.

Some people think that the slight beveling of edges of planks that are prefinished is a drawback, but it’s more of just an aesthetic preference. Some people really want a look that is as flat as possible, so they go for unfinished floors that can be sanded completely flat before finishing. Most people don’t seem to mind, however, because of the added durability and ease of installation on prefinished floors.

For a really great video on Uniclic profile options and how installation works, check out this video from the creator, Unilin Technologies.

Uniclic® Locking System

One method of securing bamboo flooring planks during installation is by using click lock floors that have the Uniclic® Locking System. Uniclic is a patented securing system added during the manufacturing process with a unique tongue-and-groove being added to each plank.

Many homeowners seeking bamboo flooring look for the Uniclic feature because it makes installation so much easier. There’s no need to glue or nail each plank to the floor, making things very simple. It takes some of the guesswork out of installation because Uniclic provides a tight seal by simply angling and clicking the pieces together. This eliminates the risk of creating an uneven floor by messing up the installation process. And, no clean-up! Total win!

The addition of Uniclic doesn’t change much of the manufacturing process because the main plank is still the same. Fabricating a Uniclic plank simply changes the tongues and grooves on the edges, so the look of the flooring is identical to planks that use a different installation method.

Hardwood Floor Manufacturing

Hardwood floors are often another option people think about when they consider buying bamboo flooring. Often we hear people say they ultimately chose bamboo for the durability, the look, or sustainability concerns. Another thing to think about when deciding on whether hardwood is right is in the manufacturing process. Many hardwood flooring manufacturers have come under fire for shipping subpar materials.

The takeaway is that you need to know about how the product was manufactured before you buy. Often the cheapest option is cheap for a reason, whereas other companies may have something only slightly more that turns out to be a much better product, created responsibly, and sold to you honestly.